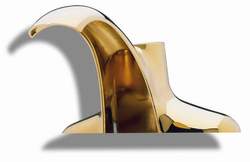

Casting Study: Bathroom faucet – Delta Faucet

Elta’s faucet construction is known as shell technology. It features a die-cast zinc cover, or escutcheon, over a brazed copper and brass assembly. The thin zinc cover is much more uniform than brass; it provides near net shape die casting with tolerances of 0.005 in., requiring less polishing. Belt sanding is used simply to remove the parting line edge where the two halves of the die meet. Shell construction maintains air insulation between the two assemblies, reducing heat transfer and accidental burnings. After machining, minor polishing and buffing, the faucet shells are copper-nickel-chrome electroplated. These assemblies are then coated by physical vapor deposition (PVD) with a proprietary high technology intermetallic finish. The zinc shell construction is preferred to plastics in both Europe and the USA. Consumer perception of the light weight and “tinny” sound of plastics is that such faucets must be lower in both quality and value.